為什麼喜歡植鞣革

為什麼喜歡植鞣革

文 ● 張岱明

引言

好像在1986年,美國的一份皮革與製鞋雜誌,登了一個廣告,有數量達到八百噸的栗木Chestnut植物單寧要拍賣,大家都覚得好奇,怎麼突然會有這麼多的存貨要求售,因為植鞣皮已經不是主流的産品,市場沒有這麼大的鞋底牛革需求,後來才發現是美國國防部把庫存的戰略物資清倉,因為二次大戰期間,牛皮及植物單寧都是戰略物資,必須維持一定數量的庫存。後來,由於橡膠製品的出現,鞋底採用橡膠取代了皮革,所以栗木單寧也不再是戰略物資,因此在市場出售。

在西元 1858 年之前,所有的皮革都是稙物單寧酸鞣製的,一直到二次世界大戰 後,才逐漸消失或是減少,台灣在二十多年前已經不再生產全植鞣牛皮了,相 對於鉻鞣皮,植鞣皮是比較傳統而費時的生產工藝,所以目前為止,鉻鞣方式生產的 皮革製品,佔了九成以上的市場。水埸前段生產過程中,植鞣皮用的是植物單寧,俗 稱栲膠,所以植鞣皮也叫做栲膠皮,在廣東一帶,因為植物單寧叫做樹膏,所以也 叫樹膏皮,在台灣用台語唸的音是澀木皮。

植物單寧是取自於大自然中的樹木抽取物 wattle extracts,比如像栗木 Chestnut, 楊梅荊木 Mimosa,橡木 Quabraqio,檳榔木 Gambier,塔拉 Tara等,因為可以生物降解 biodegradable,所以有人說比較環保。

而鉻鞣皮用的是鉻塩 chrome salt,或是硫酸鉻,溶水性佳的無機塩,使皮革鞣 製過程縮減至一晚或是更短,鉻鞣,相對於傳統的植鞣製程技術,可以増加皮革的豐 満感,也可以增加皮革物理強度,增加皮革面積,保存期限長,所以目前世界上大部 分皮革工廠,都是用鉻鞣為生產方式,鉻鞣皮在製造過程中,也可以做到最好的清潔 生產方式,可以回收廢水,不會造成汚染,所以不一定鉻鞣皮就不環保,目前鉻的回 收率都在 97%以上,而是看工廠願不願意投資做環保工程。

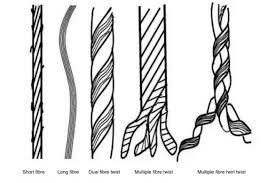

在一百多年前生產植物鞣皮有一種特性,就是存放在空氣中越久,因為氧化及日 曬雨淋的關係,就會隨著時間流逝,變成深色,甚至於多色深淺差異的 PATINA 效果。 由於當時生產的栲膠(植物單寧 vegetable tannin)品質不夠純及穩定,再加上使用 的油脂品質,在製造過程不夠完善,所以植物鞣皮有一種強烈的味道,有人喜歡有人 討厭,當時生產方式,就是把脫毛後的酸皮,垂直立置浸泡在水池 pit,經常去翻動, 不時加入植物單寧,從幾個星期到幾個月,甚至一年,譲鞣酸取代水留在皮內,也把 動物蛋白轉換成纖維組織,然後加入油脂,乾燥後,皮就成了革,再也不會腐爛了。

而現在除了少數以鞋底重革為主要產品的皮廠,還是用 pit tan 水池浸鞣外,大 部分都已經改成轉鼓鞣皮,生產效益就增大了,也可以配合市場需求而供應。

由於科技的進步,合成皮已經做得像皮革,應用在生活的每一個部分,所以壓縮 天然皮革的市場,由於價格差異相當大,一些比較普通的產品,都已經被合成皮取代, 但是植物韖革由於它的特殊性,不容易被合成皮所仿製外,它的古典風格變色的效果, 也是在合成皮上做不到,至少到現在還是沒有。另外,植鞣皮特有的皮革味道,是合 成皮仿不出來的。

這也是很多人喜歡用植鞣皮的皮革製品的原因,因為沒有人會懷疑是假皮做的! 而且,皮革塗飭的科技進步,現在也可以在植鞣皮上做到各種彩色,變色,油蜡效果。

植鞣皮的訂價,有以呎數計,也有以公斤計,後者通常是重革或是底革,厚度大都是在3mm以上到6mm.

資料來源:皮革與生活

Why People Love Vegetable-Tanned Leather

By: Zhang Daiming

Introduction

In 1986, an American leather and shoemaking magazine featured an advertisement that piqued public curiosity. It announced the auction of 800 tons of Chestnut vegetable tannins. At the time, vegetable-tanned leather was no longer mainstream, and people wondered why there was such a large stock for sale. It later turned out that the U.S. Department of Defense was clearing their strategic reserves, which once included leather and vegetable tannins as critical wartime resources.

Historical Background

Prior to 1858, all leather was vegetable-tanned. However, this changed after World War II, when the industry shifted towards chrome-tanned leather. In Taiwan, production of full vegetable-tanned leather ceased over twenty years ago. Compared to chrome-tanned leather, which accounts for over 90% of the market today, vegetable-tanned leather employs a more traditional, labor-intensive process.

Environmental Consideration

Vegetable tannins are extracted from various types of trees such as Chestnut, Mimosa, Quabraqio, Gambier, and Tara. Because these tannins are biodegradable, many consider vegetable-tanned leather to be environmentally friendly. In contrast, chrome-tanned leather uses chrome salts or chromic acid, which, although recyclable, have raised environmental concerns.

Unique Characteristics

One unique trait of vegetable-tanned leather is its ability to develop a patina over time due to exposure to air, sunlight, and rain. However, the strong scent that comes from this leather can be polarizing—some love it, some don’t. Traditional production methods involved soaking the leather in tanning pits for several weeks to months, even up to a year, to allow the tannins to replace the water content in the leather and stabilize the animal protein.

Current Trends

While some factories still use pit tanning for heavy-duty shoe soles, most have switched to drum tanning to improve production efficiency and market responsiveness. Advances in synthetic leather have also compressed the market for natural leather. However, the unique characteristics of vegetable-tanned leather, such as its ability to develop a patina and its distinct smell, make it irreplaceable in the eyes of many.

Why Do People Love It?

- Authenticity: No one doubts that products made from vegetable-tanned leather are genuine.

- Technological Advancements: Modern techniques allow for various colors, shades, and wax effects on vegetable-tanned leather.

Pricing

Vegetable-tanned leather is priced either by square footage or by weight. The latter is usually for heavy leather or sole leather, generally ranging from 3mm to 6mm in thickness.

In conclusion, the enduring appeal of vegetable-tanned leather lies in its unique characteristics, which have not yet been replicated by synthetic alternatives. This makes it a preferred choice for those who value authenticity and traditional craftsmanship.